Description:

Description: Made of heat-resistant fabric, insulating cotton, and heat-resistant steel wire stitching, it helps various equipment and pipelines achieve the effect of heat insulation, sound insulation, insulation, and energy saving, subverting the traditional fixed insulation.

Due to the differences in traditional insulation methods, equipment may be insulated but heat loss may still occur inside, making it impossible to achieve the most cost-effective energy savings for the owner. In addition, traditional insulation cannot be reused, and each time the equipment is repaired or maintained, it must be re-made and installed, causing the owner to spend money again. The removable insulation jacket can overcome the disadvantages of traditional insulation. It can be customized according to the owner's needs, achieve the benefits of insulation and energy saving, and greatly reduce the time, materials, and labor costs of maintenance.

Applications:

Applications: Generally used in steel plants, oil refineries, power plants, chemical plants, electronics factories, and science parks, the removable insulation jacket is used for insulation of pipelines, flanges, valves, hand holes, manholes, pressure vessels, heat exchanger end plates, turbine generators, and filter insulation systems.

Advantages:

Advantages: 1. Reusability

2. Easy to remove and install

3. Significantly reduces operating costs

4. Reduces machine operating environment temperature, thereby achieving energy saving

5. Installation process can reduce personnel allergies to heat-resistant materials and on-site pollution

6. Customizable to different machine and pipeline shapes

7. Excellent insulation and heat preservation effect

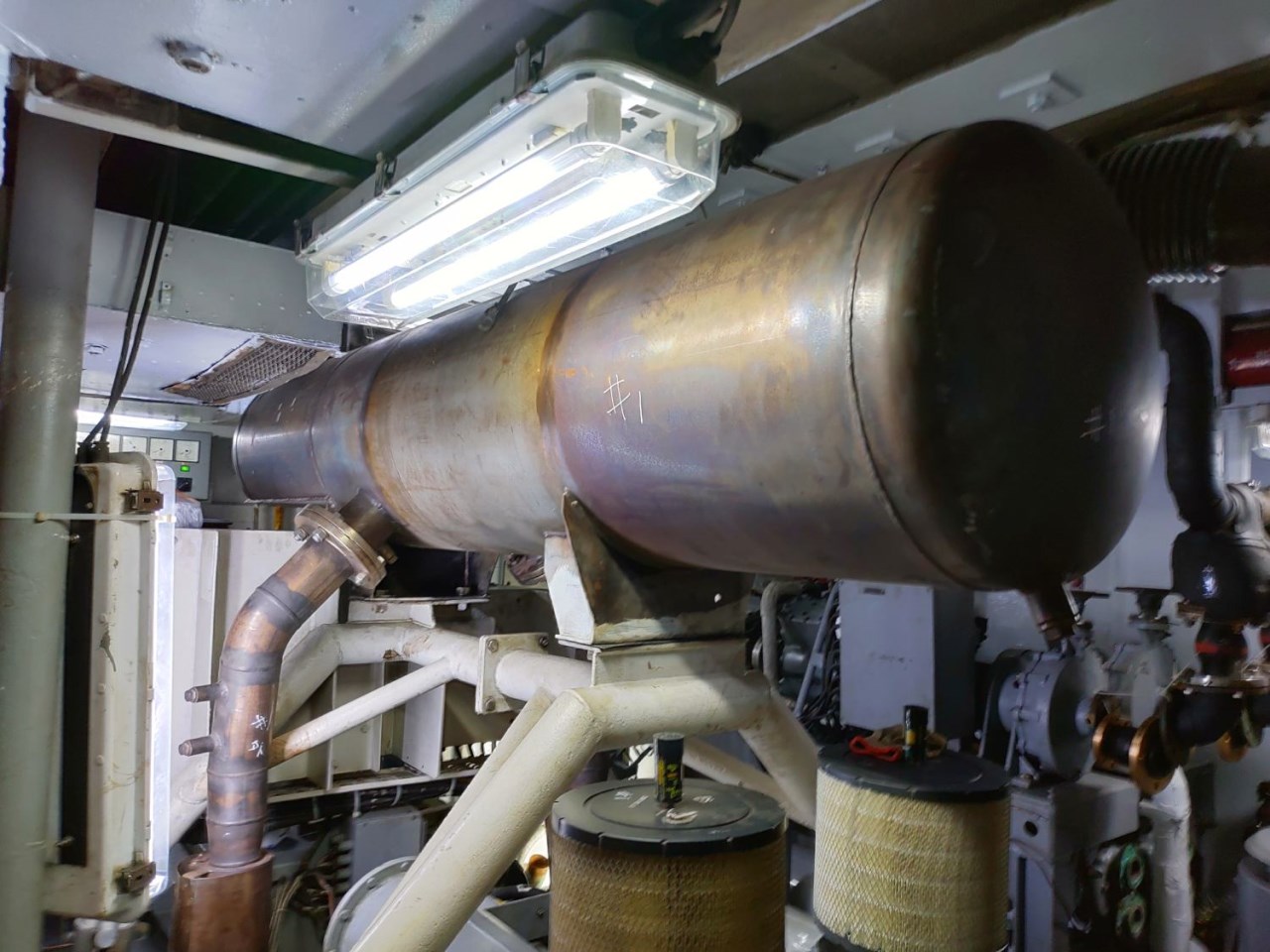

Machine Equipment Insulation Jacket(Before Installation)

Machine Equipment Insulation Jacket(After Installation)