Description:

Description: Used as a substitute for traditional metallic expansion joints, it can avoid problems such as structural spacing, wear and tear, acidic or alkaline media, extreme temperatures, vibration, moisture accumulation, and pressure.

Its shape and size can be customized according to customer requirements.

Applications:

Applications: Mostly used in public utilities such as refineries, steel plants, power plants, petrochemical plants, paper mills, waste heat recovery, and co-generation facilities.

Advantages:

Advantages: 1. Easier to install and replace than metal expansion joints

2. More vertical and horizontal offset capabilities

3. Customizable design and fabrication to accommodate conditions such as high temperature and chemical resistance

4. Absorbs noise and vibration

5. Compensates for thermal expansion

6. Designed temperature can reach up to 1000°C, pressure range -0.1kg/cm2 to 0.5kg/cm2.

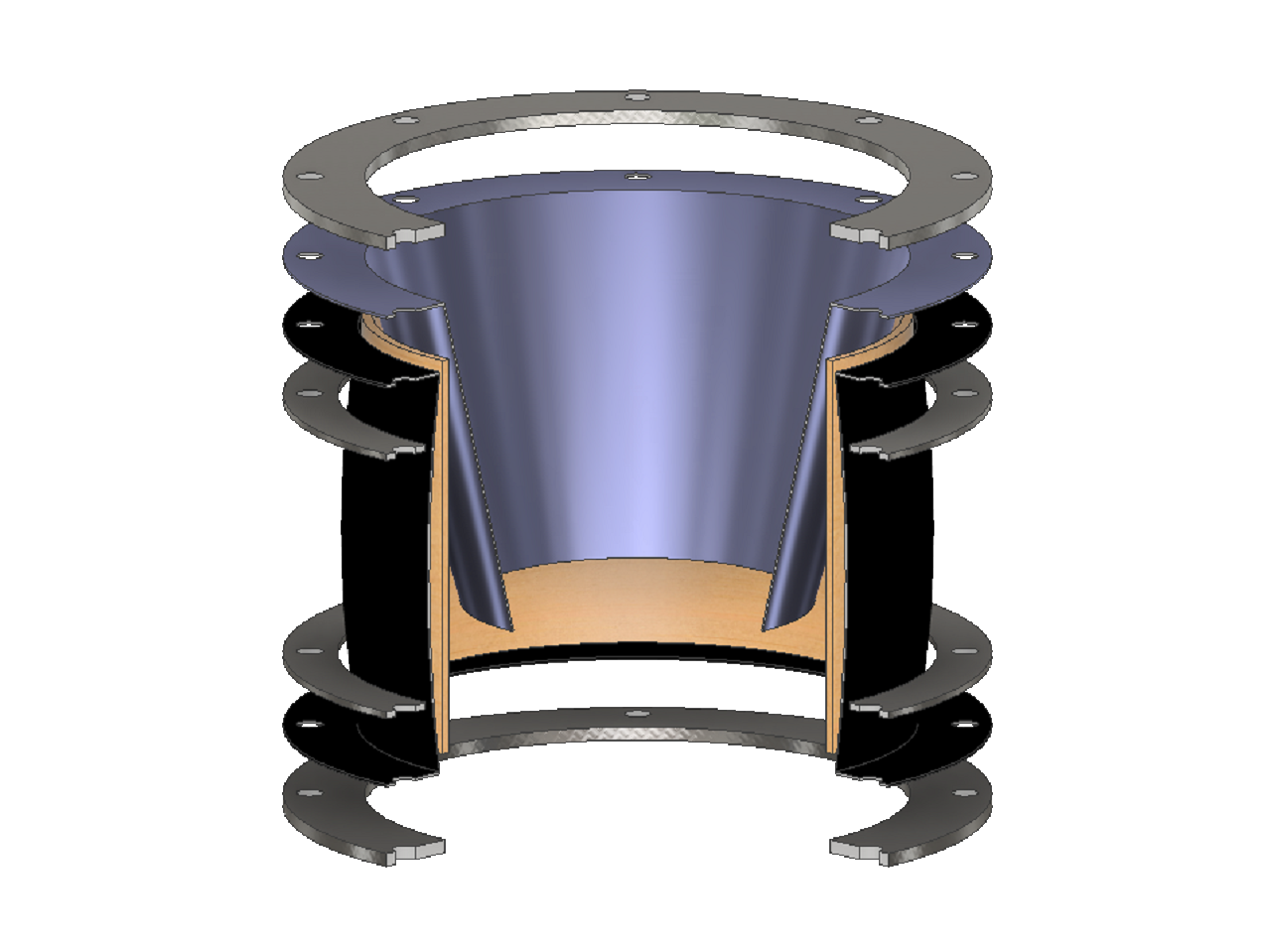

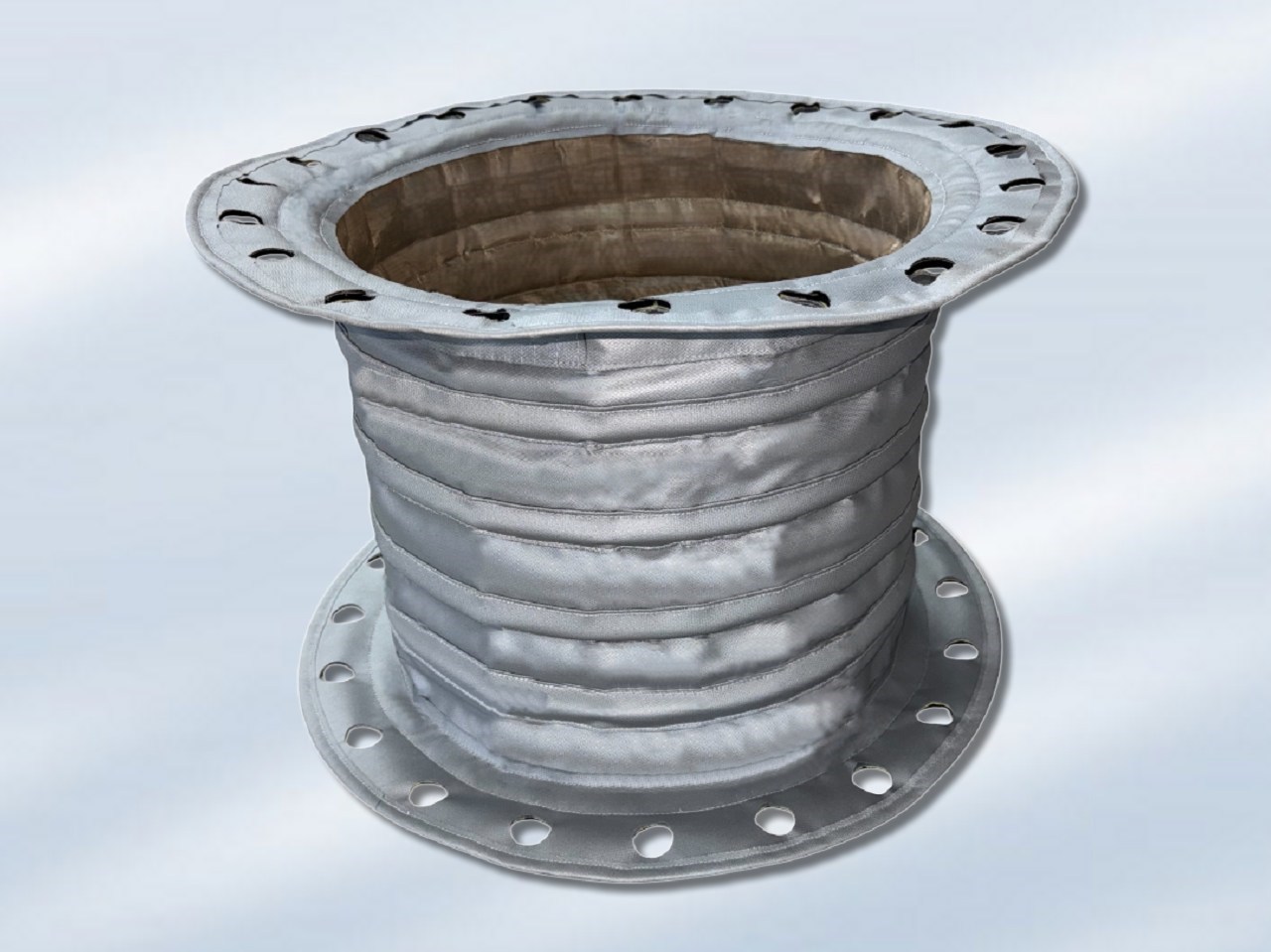

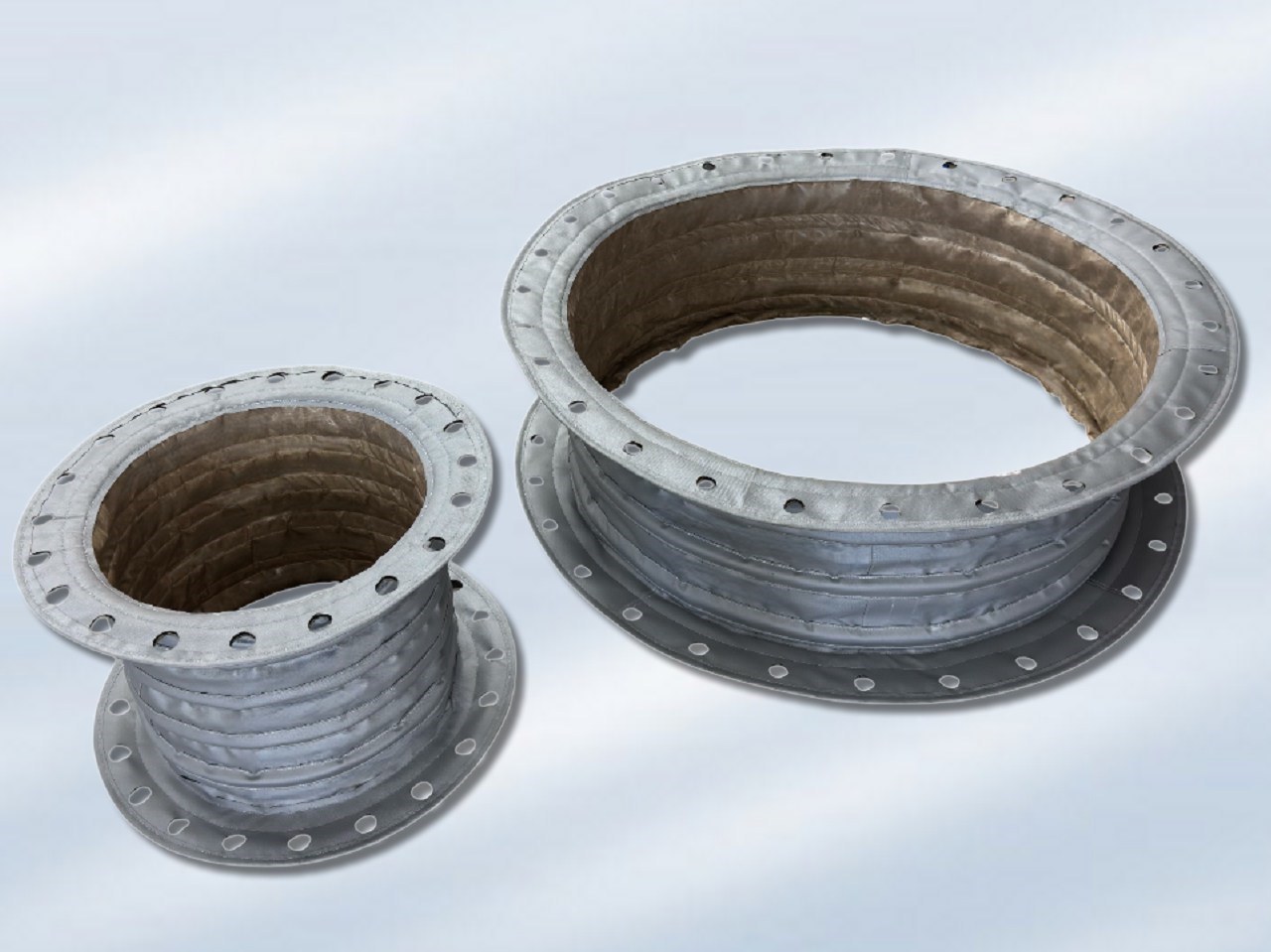

Circular Expansion Joint-Figure One

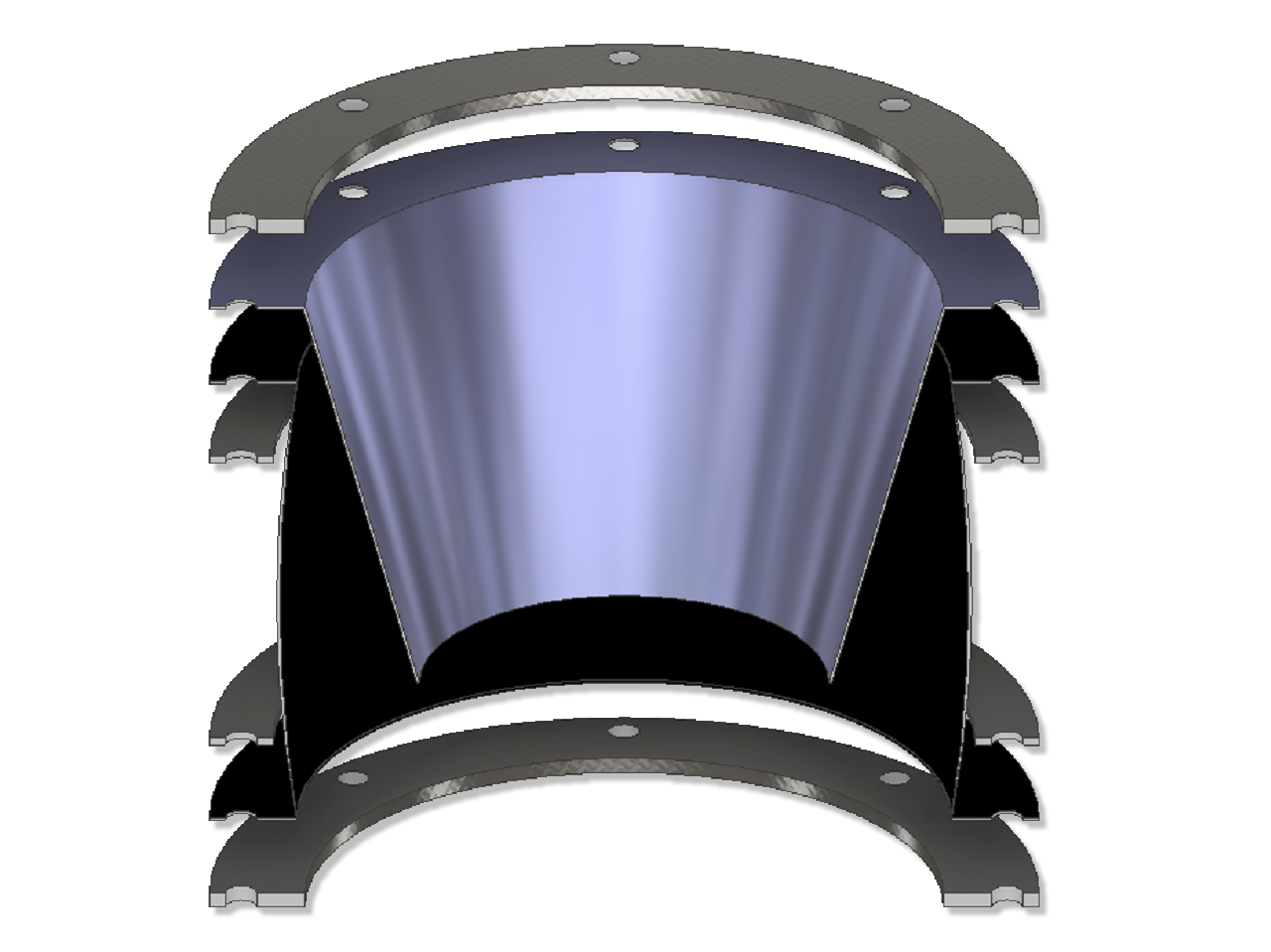

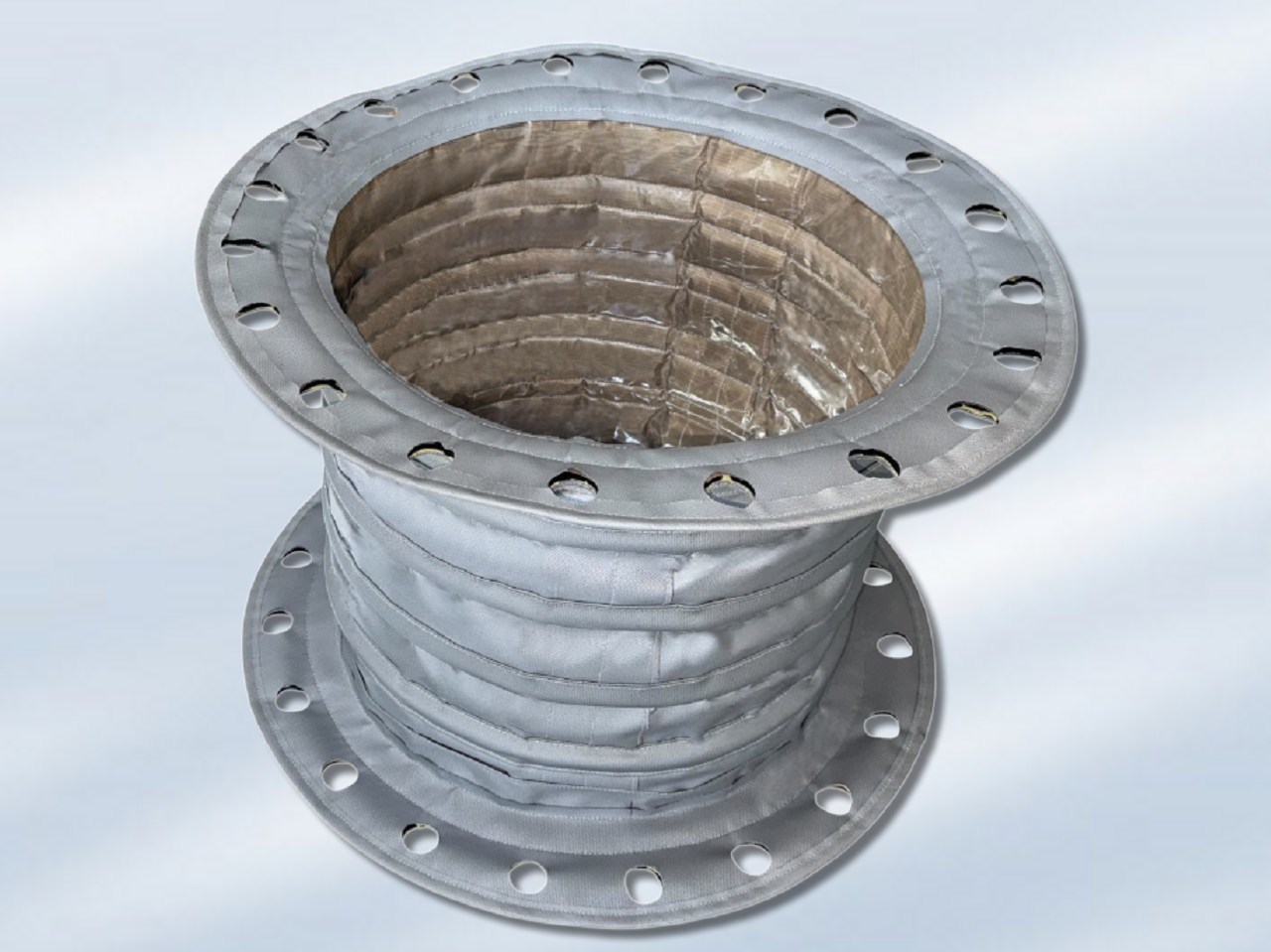

Circular Expansion Joint-Figure Two

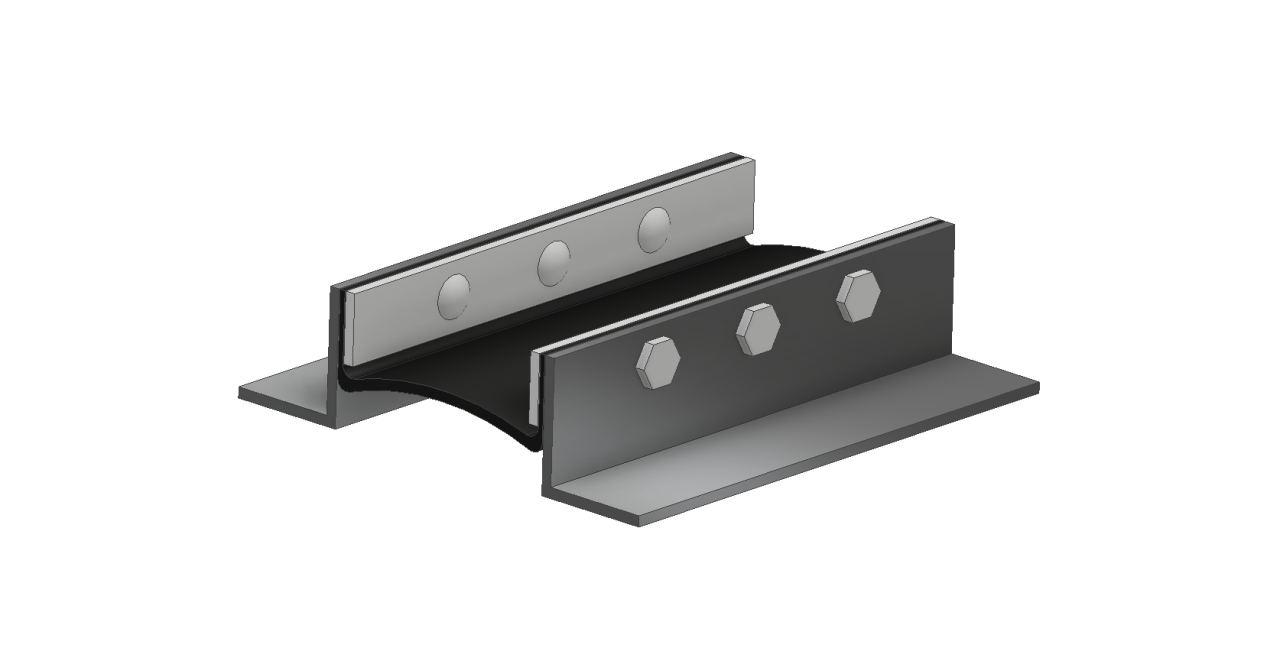

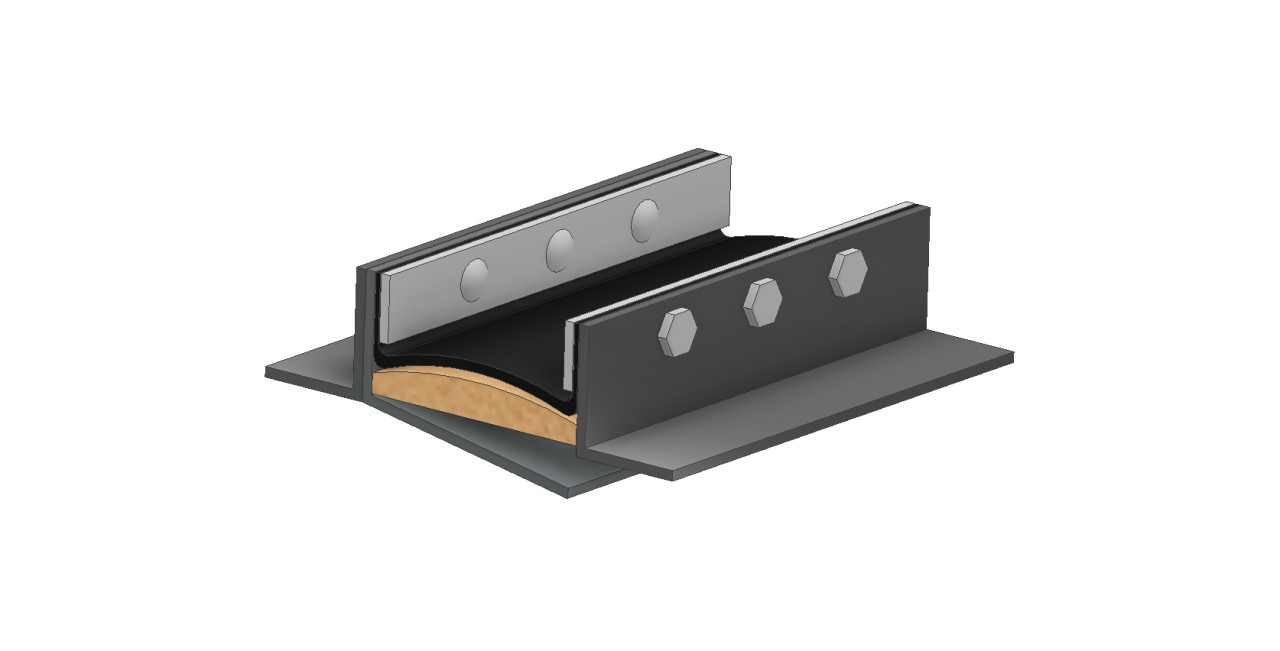

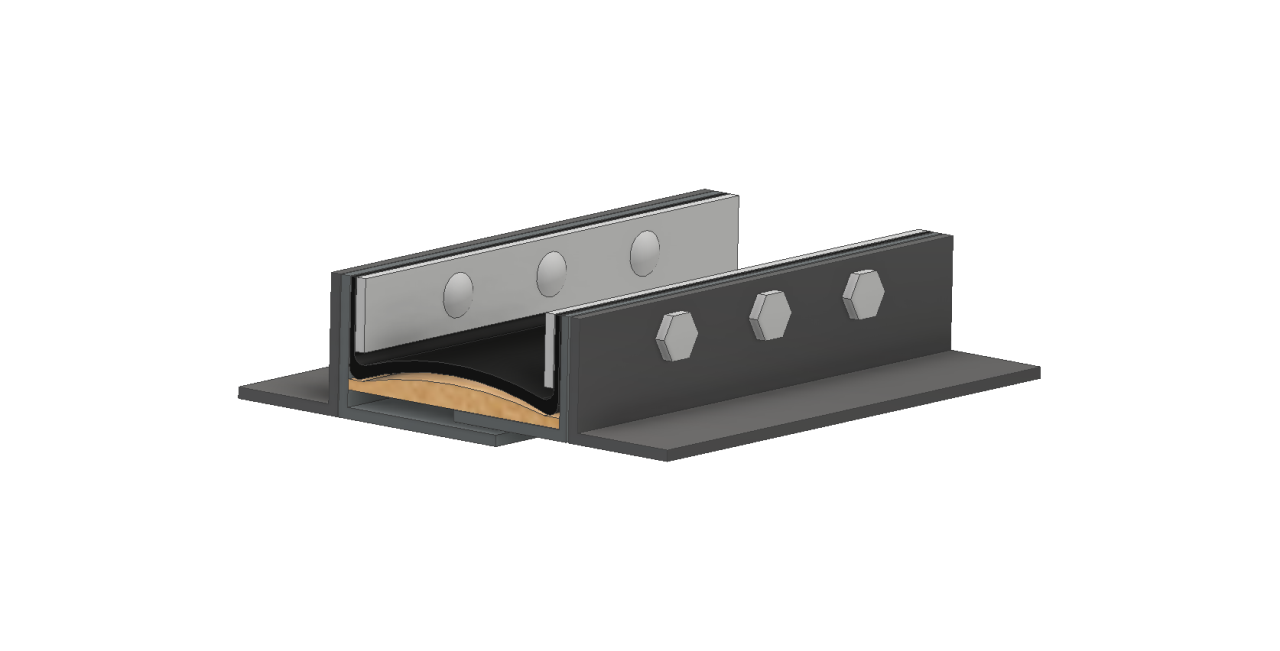

Circular Expansion Joint U-Type-1

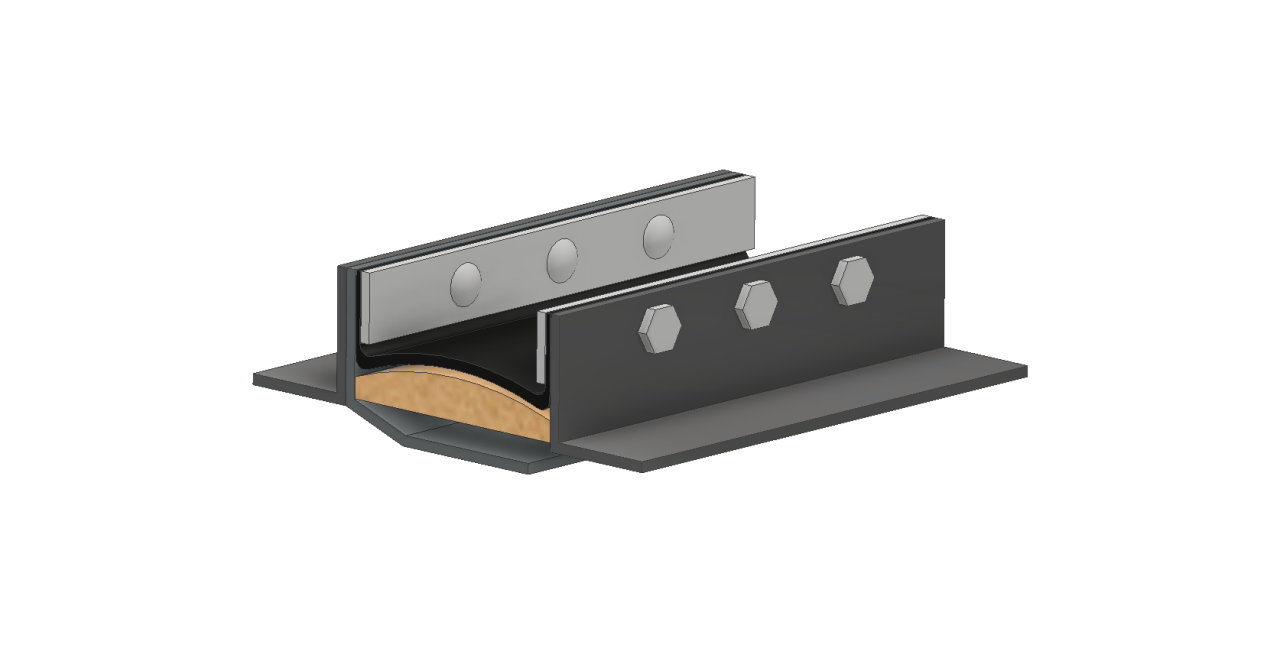

Circular Expansion Joint U-Type-2

Circular Expansion Joint U-Type-3

Circular Expansion Joint U-Type-4

Circular Expansion Joint-1

Circular Expansion Joint-2

Circular Expansion Joint-3

Circular Expansion Joint-4